Sound Sense

This project was completed during my 5th semester as part of a four-person design team. The goal was to develop a series of three speaker models for a defined user group. A key constraint was that at least 80% of the components had to be shared across all three models—how we defined and achieved this reuse was entirely up to us.

Our chosen user group was blind and visually impaired individuals, and the project was developed in close collaboration with people from that community. Through interviews, testing, and feedback sessions, we identified specific needs and preferences that guided our design decisions. The result was a set of three distinct speaker designs, each tailored to different contexts of use, but built from a shared modular system.

One of the major learning outcomes from this project was project management. We rotated the role of project manager weekly, giving each group member hands-on experience with leadership, coordination, and communication. Every week, the acting project manager was responsible for presenting our progress to the entire semester cohort—an exercise that significantly strengthened my ability to communicate clearly, lead structured meetings, and manage deliverables under time pressure.

Through this project, I developed strong skills in modular product development, inclusive design, and team leadership. I also learned the value of user-driven design processes and how to translate feedback into meaningful design outcomes. These are all skills I bring into any collaborative and user-focused design environment.

3D file

All three speaker variants were developed using Fusion 360, where I was responsible for building and organizing the CAD models. While all versions were modeled with attention to structure and internal layout, this particular model—also used as the visual prototype for our final exam—was the most detailed and refined version.

One of the key features in this model is the visible speaker drivers behind the grille, which helped communicate internal functionality and enhance realism in both visualizations and presentations.

To accurately represent the final product, I imported real-world components from manufacturers and online libraries, including drivers, connectors, switches, and fasteners. These can be seen clearly in the exploded views included in the technical drawing package.

The most important goal with the modeling process was to establish a shared 80% core across all three speaker variants. This meant carefully planning internal layouts, fastening methods, and outer dimensions so that most parts could be reused—an essential part of our modular design strategy.

This project demonstrates my ability to work systematically with modular 3D modeling, manage component libraries, and build CAD models that are both production-aware and presentation-ready.

Technical Drawings & Exploded Views

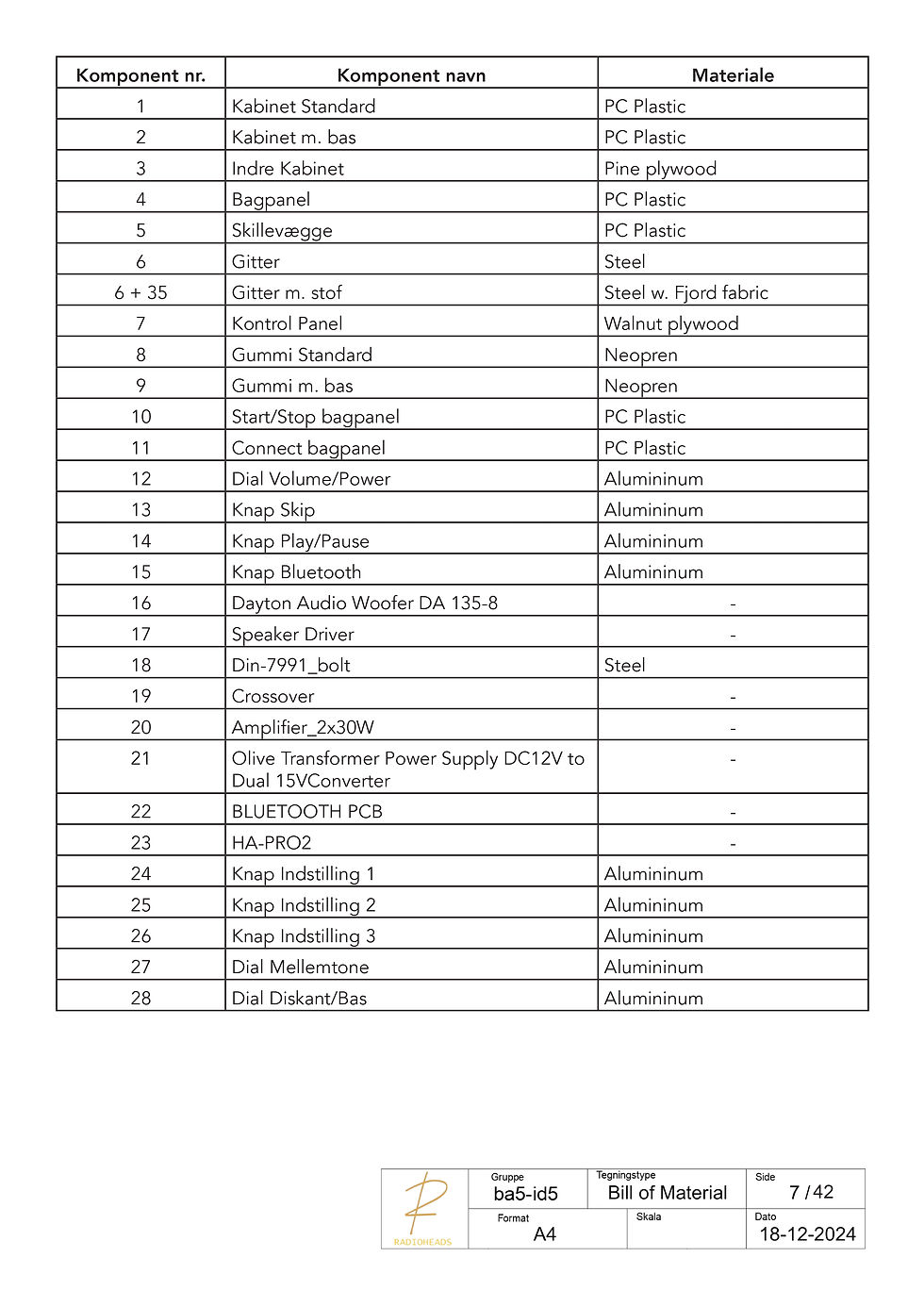

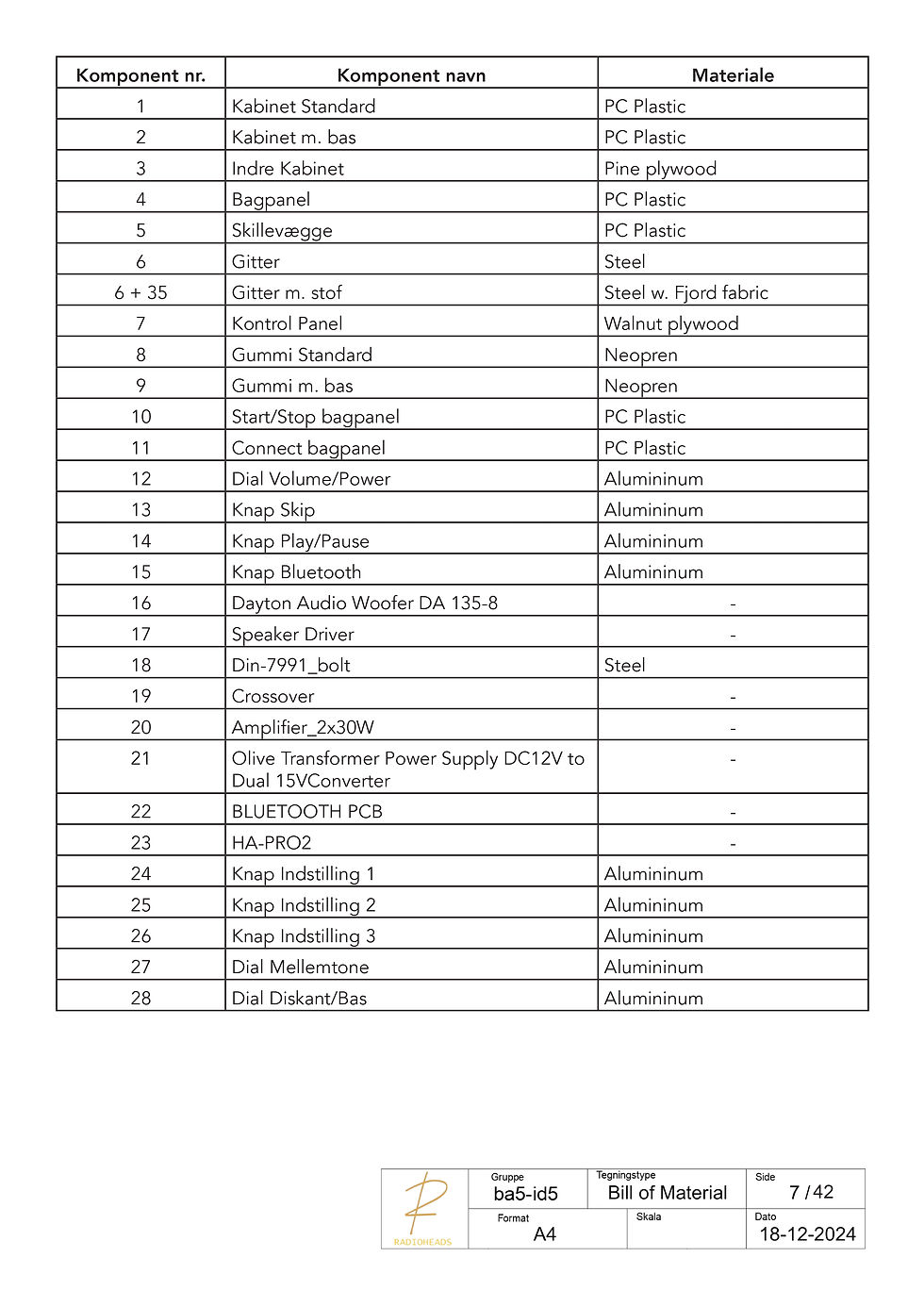

For the Sound Sense project, I was responsible for a large portion of the technical drawings. My focus was especially on creating clear and detailed exploded views and component drawings that helped visualize how the product was assembled, and how the internal components related to each other. These exploded views were carefully constructed to emphasize every part of the system, and to communicate the modularity behind the design.

A core aspect of this project was to create three speaker variants (Tune, Connect, Hub), while ensuring that at least 80% of the components were reused across all models. This approach was vital to reduce production cost, streamline assembly, and simplify part sourcing. The remaining 20% of the components were unique to each speaker variant and reflected their individual features and user scenarios.

The technical drawing package includes both standardized parts and variant-specific components, all dimensioned and toleranced according to relevant manufacturing standards. From internal PC plastic structures to plywood control panels and aluminum interface parts, the documentation is ready for both prototyping and production.

These drawings helped ensure that our modular design approach could actually be executed in practice. They provided a crucial foundation for evaluating manufacturability, compatibility, and assembly, and served as a clear reference throughout the entire design and prototyping process.

Creating this drawing set gave me valuable experience in systematic documentation, modular design thinking, and communicating complexity clearly—key skills in any product development setting.

Componants list and tecinal

I delved passionately into scrutinizing the research and vetting of the internal constituents for the audio system. From the genesis of the undertaking, I took the lead in excavating what was requisite to accomplish high-fidelity sound and distinguishing the varieties of constituents that had the capacity to render it. As the scheme advanced, and the bodily measurements for the three variants of loudspeakers were delineated, I facilitated determining which components could be normalized across the models. This demanded judicious constituent examination and equalization to maximize coherency while maintaining diversity of expression amongst the parts, achieving a harmony between standardization and versatility.

This complex project necessitated a meticulous examination and refinement of each element to guarantee that no less than four-fifths of the pieces were standard across the three audio models. Achieving such a high degree of commonality among the parts was paramount to maintaining affordable manufacturing expenses and streamlining construction. In addition to overseeing the acoustic parts, my role involved the specialized computations for the power source. The battery life estimations required factoring multiple variables to satisfy the stringent requirements for autonomy while also contemplating future expandability.

Despite not having formal training in this area, I was able to research and learn the necessary methods to make realistic power consumption and battery life estimates for the product. While the calculations weren’t perfect, they provided critical insight for the design phase—especially when it became clear that the initial battery setup would not deliver sufficient runtime.

This part of the project showcases my analytical mindset, adaptability, and ability to quickly learn new technical skills to support the design process when needed.

Production of Prototype

This is a visual prototype designed not only to communicate form and material intent, but also to simulate certain functional aspects of the final product. The prototype was assembled using 3D-printed components that were carefully post-processed to resemble cast plastic parts. Surfaces were painted to imitate metal, wrapped with a thin wooden veneer, or covered in fabric to convey realistic textures and finishes.

The goal was to create a cost-effective and quick-to-build model that accurately represented the product’s size, weight, and visual expression. To match the expected weight of the final speaker, internal ballast was added, giving testers a realistic sense of how the product would feel when handled.

In addition to its visual qualities, the prototype includes interactive features, such as buttons that behave like those intended for the final product. When pressed, they provide tactile feedback—clicking, staying in position, and functioning in a way that enabled meaningful user testing with blind and visually impaired users. This was essential for gathering early-stage feedback on the product’s physical interface.

As this is a prototype, the buttons used differ from the final production components. I selected affordable alternatives that matched the intended function and size as closely as possible. Based on the selected buttons, I modified the original 3D CAD files before printing, to ensure seamless integration.

This process highlights my ability to create realistic, testable prototypes under tight constraints, as well as my adaptability in adjusting designs for available materials and components. It also demonstrates my focus on inclusive design and the importance of hands-on user feedback in the development process.

Pitching and Project Management

I had the opportunity to step into the role of project manager as early as week 2 of the Sound Sense project. At that point, the group had just received critical feedback during our first milestone review, and my goal was to help us regain momentum. I initiated a new round of ideation and sketching sessions, aiming to shift the team’s focus toward progress and forward-thinking. I knew we had time to evolve the project, and I wanted to create an optimistic, action-oriented atmosphere that encouraged creative thinking.

As part of my responsibilities, I also had to pitch our progress to the entire semester cohort that week. My challenge was to visually communicate a core user insight: the experience of blindness. Ironically, this meant using visuals to represent a condition that is inherently non-visual. To achieve this, I developed a simple but powerful concept visualization showing that blindness is not simply “seeing black,” but a diverse and personal experience. Alongside this, I presented our early sketches and ideas to gather feedback from students and faculty.

Later in week 6, I again took on the project manager role—this time in a shared leadership format with another group member. We chose to divide responsibilities to play to our individual strengths. I focused on planning and structuring the week, including task allocation, setting overall direction, and aligning our goals. My co-lead was responsible for collecting inputs, formatting content for the report, and making sure all work was properly documented and evaluated.

To stay aligned, we held morning meetings before the rest of the team arrived, where we reviewed progress, discussed the day’s focus, and clarified expectations. This not only ensured a smoother workflow but also built a strong foundation for leadership built on trust, communication, and shared ownership.

These experiences strengthened my ability to lead under pressure, organize complex design processes, and motivate a team. I bring with me a structured, positive, and adaptive leadership style—something I look forward to developing even further in future professional settings.